While 3D printing has the potential to decentralize product design and manufacturing, nothing is without it’s drawbacks. One of the biggest for 3D printing is the inherent waste of filament packaging. Filament typically comes vacuum-sealed on a plastic spool with a tiny silica gel packet. The plastic film and silica gel are there to prevent water uptake which can have a negative impact on filament performance, and the spool is there to provide the filament with structure and an easy way to keep the long strand of plastic from tangling.

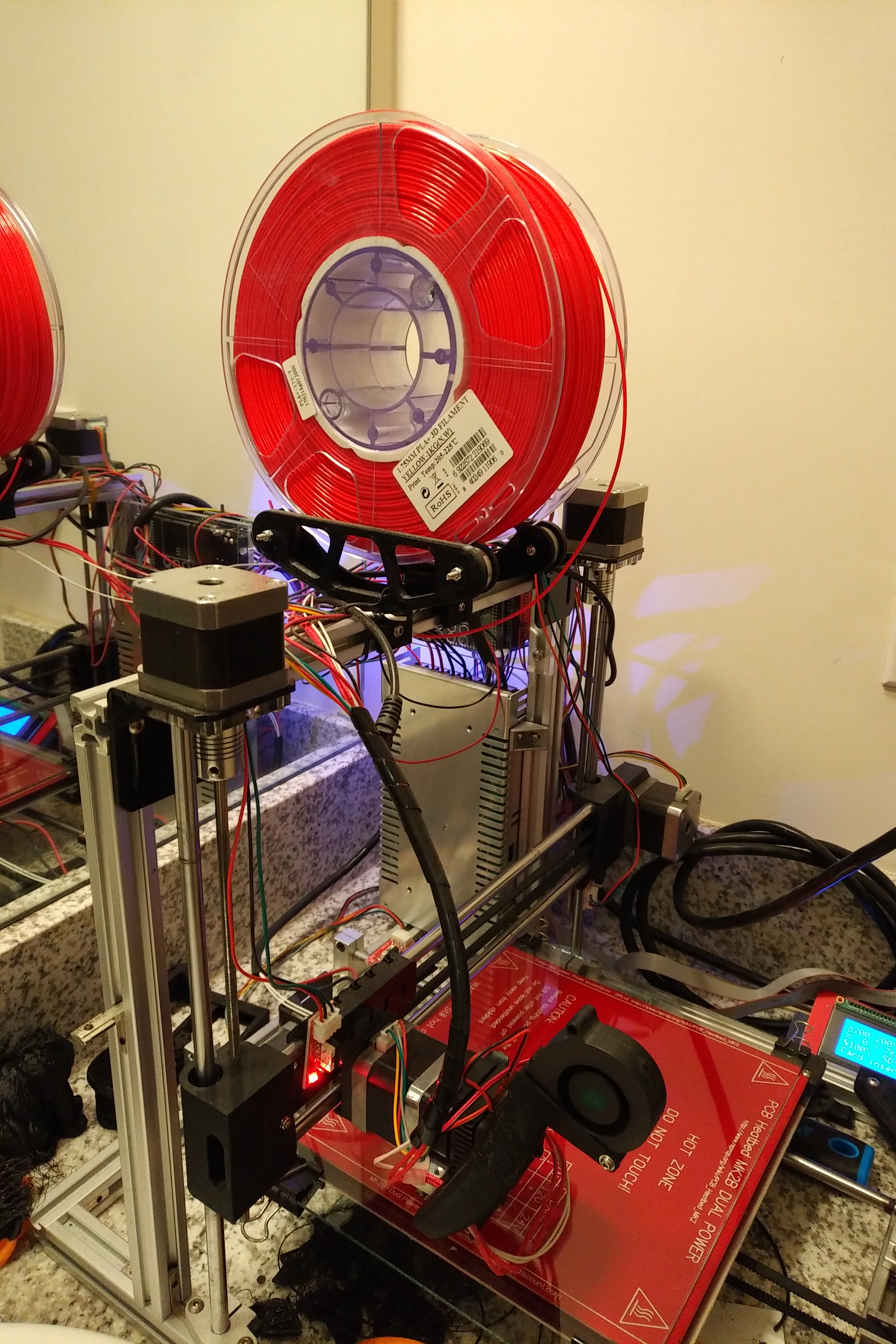

My 3D printer with one of its new Master Spools mounted on top

The problem comes when you reach the end of the spool. What are you supposed to do with an empty spool? People on Thingiverse and the other 3D printer file repositories have come up with an impressive number of solutions to reusing these empty spools, but at some point, enough is enough. Luckily, makers are an inventive bunch, and RichRap came up with a solution called the Master Spool.

By making the spool a reusable part of the 3D printing process, filament is cheaper to ship with a reduced weight and carbon footprint. Since it’s an open standard, any filament manufacturer can jump onboard and offer their filament as Maker Spool refills. Master Spool is still new enough that only a few manufacturers are supporting it so far, but the speed of adoptions makes me think this will become the new normal for 3D printer filaments.

I ordered my Master Spools from Filastruder, and so far, I’m really impressed by the quality of the filament and how simple it was to put the Master Spool together. Two bolts and cutting three zip ties is all it takes to free yourself from an unending pile of empty filament spools.

The empty Master Spool

This system isn’t entirely without waste, but it’s a big improvement over what came before. The plastic film can probably be recycled with other plastic bags in your area (usually at grocery stores), but I’m not sure what to do with the zip ties other than throw them in the trash. I keep the silica gel and put it in with my filament to try keeping it dry, but if I were a manufacturer, I’d spend the little bit extra and spring for the reusable silica gel packets with color indicator to reduce waste even more.

I think this is still a win for making 3D printing more sustainable. What do you think? Let us know in the comments!

Solarpunk living includes a pretty strong waste reduction component as part of being environmentally conscientious. One of the simpler ways to reduce the amount of waste you generate is to cook your own food. While the greenest measuring cups are the ones you already have, if you are in need of a set, the

Solarpunk living includes a pretty strong waste reduction component as part of being environmentally conscientious. One of the simpler ways to reduce the amount of waste you generate is to cook your own food. While the greenest measuring cups are the ones you already have, if you are in need of a set, the